Product Details

Product Introduction

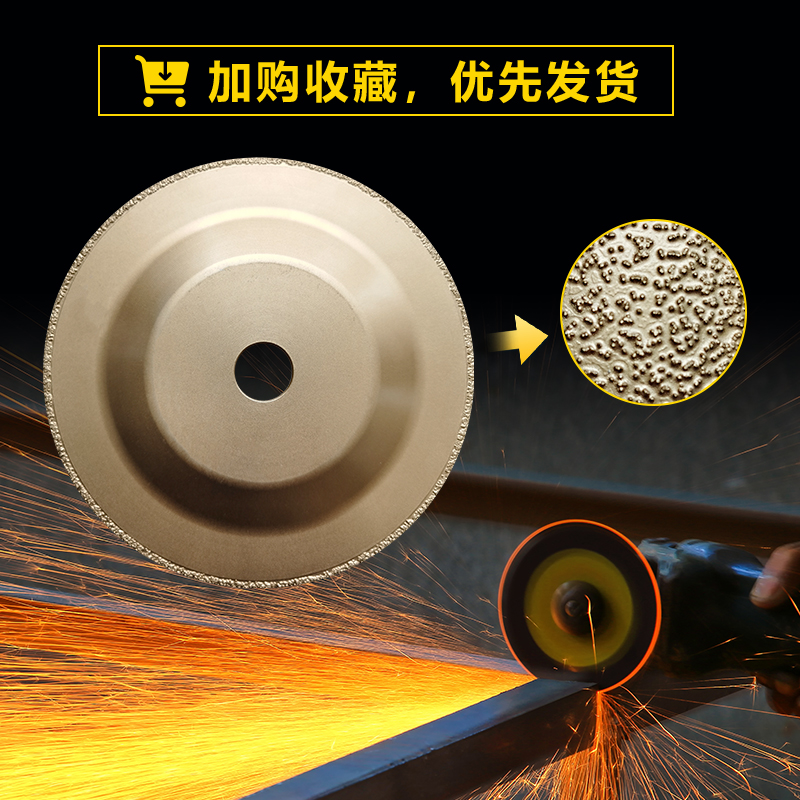

Henan Youde Superhard Tools Co., Ltd. (UHD) specializes in the research, development, and production of efficient and durable brazed diamond cup grinding wheels. These wheels utilize high-quality diamond grit and advanced brazing processes to significantly enhance grinding efficiency and wear resistance. Designed to high industrial standards, these wheels are suitable for precision machining of a variety of hard materials, including gray iron, ductile iron, stainless steel, carbide, stone, glass, and ceramics. These cup grinding wheels feature impact resistance and an anti-chipping structure, ensuring safe and stable machining. Available in sizes ranging from 100 to 180 mm in diameter, they meet the demands of machining complex curved and flat surfaces. UHD strictly adheres to the ISO9001 quality management system, ensuring that every product meets international trade standards. They offer a 7-day, no-questions-asked return and exchange policy, a 12-month warranty, comprehensive after-sales service, and 24/7 technical support, ensuring a worry-free purchasing experience. Choosing UHD brazed diamond cup grinding wheels offers an efficient, stable, and safe solution for machining superhard materials.

Advantages and features

1. High-quality diamond particles ensure excellent wear resistance and long service life; 2. Advanced brazing technology improves grinding efficiency and material bonding strength; 3. Anti-chipping design ensures smooth and safe processing; 4. Multiple customization options meet processing needs of different sizes and shapes; 5. Strong impact resistance to adapt to complex industrial environments; 6. Strict quality control, compliant with ISO9001 international certification standards; 7. Comprehensive after-sales service: 7-day no-questions-asked return and exchange policy, 12-month quality assurance, and 24/7 technical support.

Application Scenario

It is widely used in the field of industrial manufacturing, including precision grinding of ductile iron, gray iron, stainless steel and cemented carbide; it is suitable for stone processing, glass polishing and ceramic surface treatment; it provides an ideal solution for mechanical processing, mold manufacturing, stone processing and surface treatment of high-hardness materials; it is particularly suitable for customers who require high precision and high wear resistance for metal and non-metal hard material processing.