Product Details

Product Introduction

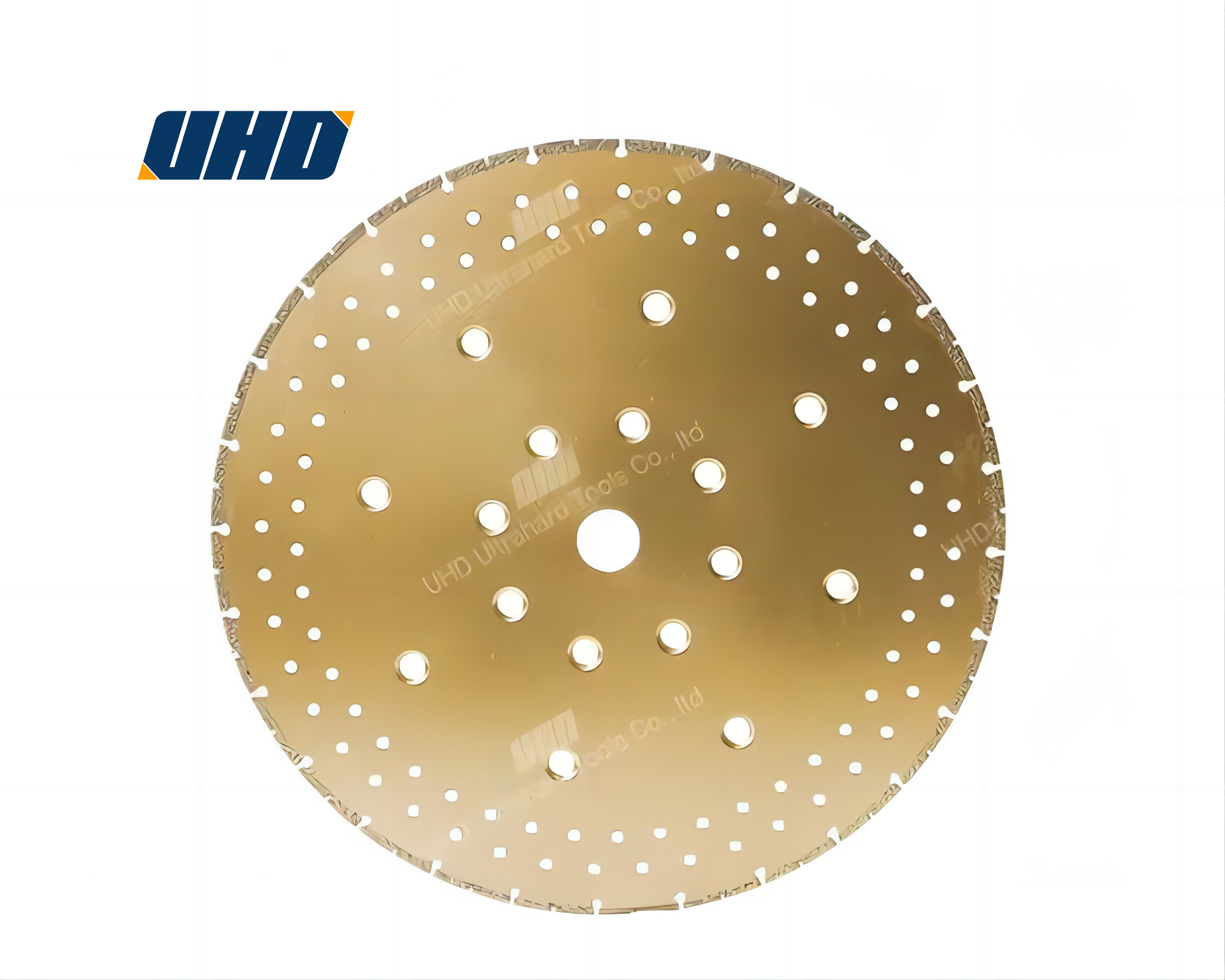

Henan UHD Superhard Tools Co., Ltd., leveraging its leading brazing technology and high-quality diamond particles, has created a series of highly wear-resistant and long-life brazed diamond grinding discs. Product diameters range from 100mm to 180mm, supporting both flat and curved surface designs to meet the surface machining needs of various workpieces. They are particularly suitable for high-intensity grinding of a variety of hard materials such as gray cast iron, ductile iron, stainless steel, cemented carbide, stone, glass, and ceramics. UHD grinding discs possess excellent impact resistance and stability, adapting to high-load industrial machining environments and significantly improving grinding efficiency and tool life. A rigorous quality control system and ISO certification ensure the superior performance of every product, supporting customized solutions for global customers. Choose UHD brazed diamond grinding discs to bring a precise, efficient, and durable grinding experience to your production processes.

Advantages and features

1. Advanced brazing technology is used to ensure that the diamond particles are firmly bonded together, extending the service life.

2. Multiple sizes and flat/curved surface designs to meet diverse material processing needs.

3. Excellent wear resistance and impact resistance, suitable for high-load industrial applications.

4. Wide range of applications, including steel, cemented carbide, ceramics, glass and stone.

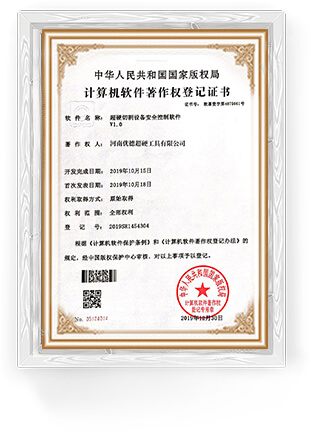

5. Strict quality management and ISO certification ensure product stability and safety performance.

6. Supports customized production to meet specific customer processing requirements.

7. UDE is a reputable brand that provides professional technical support and comprehensive after-sales service.

Application Scenario

This product is widely used in machinery manufacturing, mold making, stone carving, glass and ceramic precision machining, and stainless steel and cemented carbide parts grinding, meeting the needs of industrial customers for high wear resistance and high precision grinding tools. It is particularly suitable for customers in the automotive, aerospace, electronics, construction, and industrial equipment manufacturing industries who prioritize processing efficiency and surface quality.

.png?x-oss-process=image/resize,m_fill,h_300,w_300/format,webp)